Welding activities generate complex airborne contaminants that pose a recognised risk to worker health if not properly controlled. Welding fumes contain a mixture of fine particulate matter and gases that can penetrate deep into the lungs when inhaled. Under Australian work health and safety legislation, PCBUs are required to identify, assess and control exposure to welding fumes to protect workers and others in the workplace.

Audiometrics and Medical Personnel provide specialist welding fumes assessment and occupational hygiene services across Victoria and New South Wales. Our assessments are designed to support compliance, protect worker health and provide defensible evidence for regulators and auditors.

Welding fumes are formed when metals are heated above their boiling point and condense into fine airborne particles. The composition of welding fumes varies depending on the welding process, base material, consumables and surface coatings.

Common components include:

Safe Work Australia identifies welding fumes as hazardous airborne contaminants due to their ability to cause both acute and chronic health effects. The International Agency for Research on Cancer classifies welding fumes as carcinogenic to humans, reinforcing the need for robust exposure management.

Different welding methods generate different fume profiles and risk levels.

Understanding the mix produced by each process is the starting point for a robust welding fumes risk assessment.

Safe Work Australia has reduced the workplace exposure standard for welding fumes (not otherwise classified) from 5 mg/m³ to 1 mg/m³ as an eight hour time weighted average. WorkSafe Victoria and other state regulators now expect PCBUs to review and upgrade controls to meet this tighter limit. Employers must also ensure exposure to individual fume components such as chromium VI, manganese and ozone does not exceed their specific workplace exposure standards.

Failing to control hazardous airborne contaminants from welding is a breach of WHS/OHS law and can result in enforcement action, workers’ compensation claims and long term health impacts for welders.

| S. No. | Guideline / Requirement | Key Focus | Jurisdiction / Source |

|---|---|---|---|

| 1 | Workplace exposure standard for welding fumes (not otherwise classified) – 1 mg/m³ (8 hour TWA) | Sets the maximum average concentration of total welding fume in a worker’s breathing zone over a standard shift. | Safe Work Australia : Workplace Exposure Standards for Airborne Contaminants |

| 2 | Exposure standards for individual metals and gases in welding fumes (for example chromium VI, manganese, ozone, nitrogen dioxide) | Defines specific limits for hazardous constituents within welding fume and gases that must not be exceeded. | Safe Work Australia : Workplace Exposure Standards for Airborne Contaminants |

| 3 | Duties of PCBUs to manage risks from welding fumes | Requires identification of welding hazards, risk assessment, implementation of controls and safe systems of work. | Model WHS laws; OHS Act and Regulations in Victoria; WHS Acts in NSW and other states |

| 4 | Use of the hierarchy of control for welding processes | Emphasises elimination, substitution and engineering controls before administrative controls and PPE. | Model Code of Practice: Welding processes |

| 5 | Atmospheric (air) monitoring where uncertainty or potential health risk exists | Requires PCBUs to carry out air monitoring for airborne contaminants, including welding fumes, to verify control effectiveness. | WHS/OHS regulations and guidance on airborne contaminants |

| 6 | Health monitoring for workers exposed to specific welding fume constituents | Obliges PCBUs to provide health monitoring where workers are exposed to substances such as hexavalent chromium, cadmium or inorganic lead in welding fume. | Safe Work Australia – Health monitoring guidance https://www.safeworkaustralia.gov.au/topic/health-monitoring |

| 7 | WorkSafe Victoria – Controlling exposure to welding fumes | Provides Victorian expectations for ventilation, local exhaust, respiratory protection and exposure control for welders. | WorkSafe Victoria : Controlling exposure to welding fumes |

| 8 | SafeWork NSW guidance on welding fumes and hot work | Outlines practical control measures, confined space considerations and WHS duties for PCBUs in NSW. | SafeWork NSW : Welding and allied processes |

Audiometrics & Medical Personnel offers a complete suite of welding fumes occupational hygiene services, including:

All samples are analysed by accredited laboratories, and every project is overseen by a certified occupational hygienist.

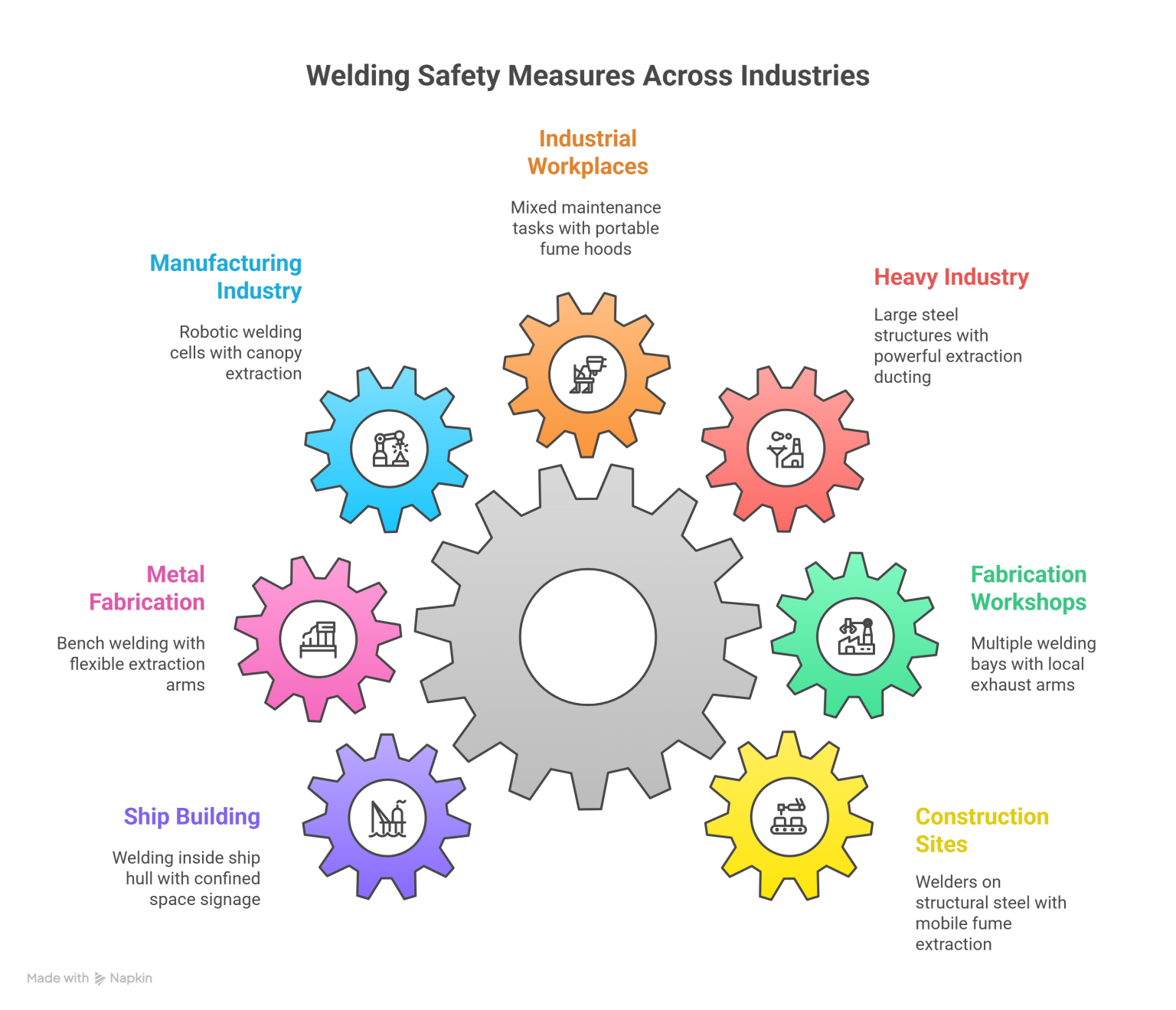

Most welders are exposed through inhalation of fumes and gases in their breathing zone. Risk increases significantly in:

Atmospheric monitoring should be undertaken whenever there is uncertainty about fume levels or a risk to worker health. Typical triggers include:

Our occupational hygienists measure welding fumes using:

Results are presented as 8 hour time weighted averages, short term exposure values and peak levels, making it clear whether workplace exposure standards for welding fumes are being met.

If monitoring shows welding fumes or specific contaminants above the WES, the PCBU must act immediately to reduce exposure. Typical steps include:

Audiometrics & Medical Personnel documents these actions in a welding fumes mitigation plan and verifies improvements through follow up monitoring.

Partner with Audiometrics & Medical Personnel for expert welding fumes assessment, personal exposure monitoring, and clear advice on ventilation, fume extraction and respiratory protection. Our certified team helps you identify hidden risks, meet Australian workplace exposure standards, and protect the long term respiratory health of your welders.

Call 03 9819 4355 or Email [email protected] to book a welding fumes assessment, request a tailored mitigation plan, or schedule a confidential discussion about your welding operations.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Audiometrics and Medical Personnel ATF The Trustee for KM Future Trust

03 9819 4355

Business Centre Entrance, C4, Level 1/2 Main St, Point Cook VIC 3030, Australia

30 A Verri Street, Griffith, NSW 2680